About Us

- SACHET PACKAGING MACHINE

- POUCH PACKAGING MACHINE

- HORIZONTAL PACKAGING MACHINE

- FILLING / CAPPING MACHINE

- FULLY AUTOMATIC SYSTEM

- MIXER / ROASTER / FRYER

- COOKING TANK / STORAGE TANK

- SEALING MACHINE FOR CARTON/BOX/POUCH/BOTTLE/CUP/VACUUM

- LABELING MACHINE

- OTHER MACHINE / EQUIPMENT

- ACCESSORIES

- Others

EXCELLENTPACK MACHINERY SDN BHD

11, Jalan TTC 12A-1, Taman Teknologi Cheng, 75260 Melaka, Malaysia.

+606-335 3663

+6016-335 3287

+6012-262 8804

+6012-262 8804

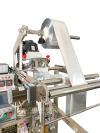

SACHET PACKAGING MACHINE | ROUND EDGE CUTTING | SERVO MOTOR | POWDER | AUGER SYSTEM

| Previous | 11 / 17 | Next |

Sachet Packaging Machine with Round Edge Cutting - Auger SystemSachet Packaging Machine | Round Edge Cutting Auger Servo Type

Description

Form of Packaging

Machine Structure and Feature

-

Servo motor to control film feeding system, higher accuracy.

-

Auger as measuring system, driven by servo motor.

-

PLC operation with touch screen control.

-

Photoelectric sensor control system.

-

Inverter to control motor speed, resulting a stable operation, lower noise, and lower failure rate.

-

Digital temperature controller, easy to operate.

-

Auto counting system, easy to monitor quantity of output.

-

Automatic measuring, filling, sealing, and date code printing.

-

Same machine can be used for different bag width by changing the former.

- Pneumatic sealing structure. ROUND EDGE can be made at sealing part.

Optional Accessories

-

Hole Punching Device

-

Sachet Linking Device

- Easy Tear Device

Optional Equipment

-

Check Weigher

-

Metal Detector

- Air Compressor

Scope of Application

- Powder – coffee powder, milk powder, cocoa powder, creamer, flour, etc

| Model | EM - 180SDA |

| Product To Be Packed | Powder |

| Capacity | 20 - 50 bags / min |

| Packaging Weight | 10g - 180g |

| Film Width | 180mm |

| Bag Length | 50 - 200mm |

| Bag Width | 20 - 80mm |

| Film Material | Heat - sealable laminated film (e.g. OPP / PE , OPP / CPP , PT / PE |

| Power Source | 220V / 50Hz / 2.2kW |

| Machine Weight | 280kg |

| Machine Dimension | L700 * W1000 * H1700mm |

Form of Packaging